Submitted: December 1997

Hello everyone!

I've finally completed chronologically-organizing my photos of the different projects I've worked on aboard my A35, Sojourn. I'd like to share some of the projects with all of you, so I thought I'd begin with my 'water tank removal process', followed by my 'Yanmar Installation'.

Before going on, I'd like to emphasize the point that I learn as I go -- I'm definitely not a boat wright (or whatever a professional boat builder is called!). I've learned a lot about working on boats from the work I did on my last boat, an Alberg 28' Triton. It seems like I'm always learning something new...with every project! Luckily, I've got good common sense and the stuff I don't know how to do -- I try to read about - talk to others that might have good opinions (or think they do), look at how they may have handled a particular project - and of course the old trial and error method... which often ends up taking a lot of time and money. And, if I'm not sure about how strong to build/fabricate something - then I usually tend to over build it!

As you know, there are often multiple ways to go about doing a particular project. What follows is the process I went through in extracting the two water tanks from the cabin sole which enables complete access to the bilge area... Hopefully this may help generate ideas for you!

WATER TANKS - Removal Process

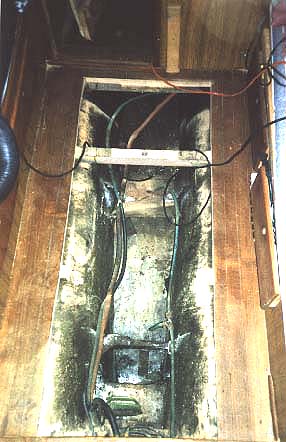

Stock Alberg 35 - There are two water tanks located beneath the main cabin sole. The only access to the tanks is through two floorboard hatches approximately 12" x 18" in size. The tanks are permanently installed under the sole; each tank sits individually on a fiberglass saddle in the keel/bilge area, about a foot or so from the bilge bottom. I didn't like the idea of not being able to have full access to the water tanks for inspection, cleaning, etc. and to the surrounding hull area.

The pilot hole was just large enough to fit the thin jigsaw blade. It was then a matter of keeping a steady hand and cutting down the length of the sole. [If you don't have a steady hand, I'd recommend rigging up a straightedge for the jigsaw.] The photo here is shot from aft, facing forward port - Nick's body is in the head area making the cut towards the stern. The forward access panel can be seen towards the middle lower right of photo.

For those of you that are interested, watch this web site for my Yanmar installation adventures!

As I look back at what I've done here, I'm glad I went ahead and went through this process of extracting the water tanks. I now have complete access to the bilge area and water tanks. If the boat wasn't over thirty years old, I probably wouldn't have done it.....or maybe I would have - I don't like the idea of not having access to the bilge/hull area! The jigsaw cuts through the sole are hardly noticeable because the cuts where made in line with the grooves already there. The cross cuts are a little noticeable....but who cares!

Once the tanks were removed, I cleaned them out and replaced them back the way they were originally....for now! I still need to completely redo all the plumbing and secure the sole with possibly a hinge up top towards the head bulkhead and add some lock down devices. At this point, I've gone ahead and am working on other projects, I'll probably be getting back to the plumbing later this winter. I'll submit another photo or two later, to show you that the cuts through the sole are hardly detectable.

I'll write again soon. Take care,

Walter,

SOJOURN